Stainless Steel Coil – 3/8″ x 50′ – DIY Chiller

We have established ourselves as a leading player in the Stainless Steel Coiled Tubing industry, supplying our products globally. Our coiled tubings meet the mechanical and chemical standards of ASTM A269, and they undergo rigorous testing, including SSC, HIC, hydraulic, and PMI tests. We also provide all relevant test certificates. As a well-known manufacturer, supplier, and exporter of Stainless Steel Capillary Tubing and Coiled Tubing, our expertise lies in delivering high-quality Seamless Capillary Tubing made from stainless steel 316 and 304, both of which offer excellent corrosion resistance. Stainless Steel Coiled Tubing is the top choice for many applications due to its superior corrosion resistance and precision. We guarantee the highest surface quality in our SS Coiled Tubing. Our 304L stainless steel coiled tubing comes polished, cleaned, passivated, and ready for immediate use. As a recognized manufacturer of SS Capillary Tubing and Coiled Tubing in China, we offer competitive prices for these products. We look forward to working with you and building a successful partnership.

Material:

American Standard Material: TP304 TP304L TP304H TP321 TP321H TP316L TP316SS

TP316Ti TP347 TP347H TP317L TP309S TP310S 904L

Russian standard Material: 08X18H10 03X18H11 10X17H13M2T 03X17H13M2

12X18H10T 08X18H10T 08X18H12B

German standard material: 1.4301 1.4306 1.4541 1.4404 1.4571 1.4550

Japanese standard material: SUS304 SUS304L SUS321 SUS316L

SUS316Ti SUS347 SUS800 SUS840

Double-Grade Material: 304/304L 316/316L 321/321H 347/347H

Super duplex steel: 2205 2304 S31803 S32750

Inconel 600,Inconel 601,Inconel 625,Inconel 725,Incoloy 800,Incoloy 800H,Incoloy 800HT,

Incoloy 825,Incoloy 901,Incoloy 925Incoloy 926 Etc.

Production standard:

China Standard : GB/T14975/14976/13296\

American Standard: ASTM A269/A312/A213/A511/A789/A790

Japanese standard: JISG3459/3463

German standard: DIN17456/17458

European standard: EN10216-5

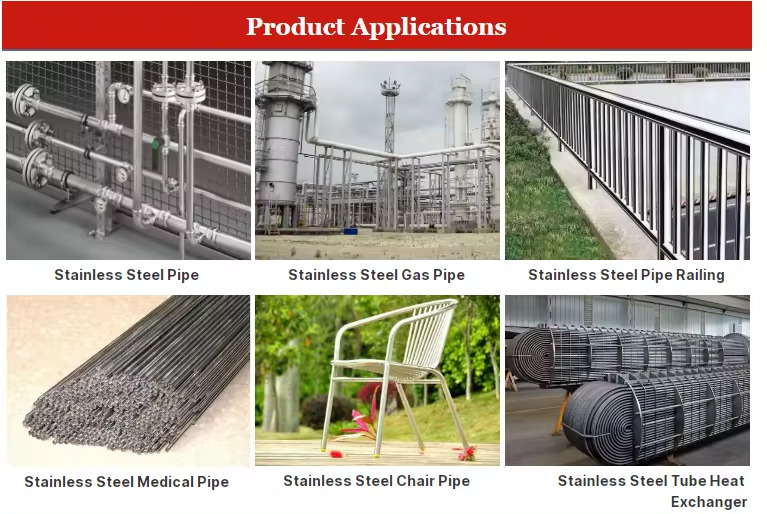

The range of applications: petroleum, chemical, pharmaceutical, food, machinery, aerospace, construction, military, hardware,gas boilers, plumbing devices, ships, power plants and other industr

For example:

1)Medical Acupuncture with Capillary Coiled Tube,

2)High-pressure instrumentation with CoiledTube,

3)Coal exploration with a stainless steel Coiled Tubing

4)Thermostat with Coiled Tube

5)Beer machine with stainless steel Coiled Tube

6)Drinking water equipment with stainless steel Coiled Tube

The manufacturing process of stainless steel capillary tubing involves several meticulous steps:

1.Extrusion: The capillary tubing is extruded from a solid billet of Type 316L stainless steel.

2.Annealing: This essential process removes temper or stiffness from the tubing, making it easy to bend and form without compromising its strength.

3.Re-drawing and Heat Treatment: The material is re-drawn through a die and heat-treated in a vacuum furnace. This step ensures uniformity and stability in the tubing’s structure.

4.Cleaning and Polishing: The tubing is worked, cleaned, and polished to achieve the desired dimensions and a pristine finish.

5.Passivation: The tubing undergoes passivation, a chemical treatment that enhances its corrosion resistance, making it ideal for use in harsh environments.

*Small Inside Diameter and Heavy Wall: This combination makes capillary tubing ideal for high-pressure applications, such as High-Performance Liquid Chromatography (HPLC) and gas chromatography. The tubing’s robust construction ensures it can withstand the rigors of these demanding processes.

*Ease of Connection: With an outside diameter of 0.064 inches, the tubing easily connects using standard 1/16” compression fittings, simplifying installation and integration into existing systems.

*Chemical Compatibility: The chemical composition of the 316L stainless steel makes it an excellent choice for laser welding tubes and assemblies, providing wide chemical compatibility and ensuring long-term performance in various environments.

*Precision and Cleanliness: Thermo Scientific™ 316 Stainless Steel Capillary Tubing is prefinished with square, burr-free ends and interiors, ensuring minimal dead volume connections. The tubing is cleaned, polished, and passivated, making it ready for immediate use without additional preparation.

-Material: 316L Stainless Steel

-Dimensions: 6x1mm

-Length: 100cm

-Model Number: 008

-Customization: Available

-Usage: DWV (Drain, Waste, Vent)

-Origin: China (CN)

This custom stainless steel capillary tubing is suitable for ultrahigh-pressure applications due to its robust construction and precision manufacturing. It is perfect for use in chemical processing, analytical instrumentation, and other industries requiring reliable high-pressure tubing.

However, it is important to note that this tubing is not recommended for biological samples. The material and manufacturing processes are optimized for chemical and industrial applications, which may not meet the stringent requirements for biological and medical use.

Conclusion

Custom Stainless Steel Capillary Tubing and Coils made from Type 316L stainless steel offer unparalleled precision, durability, and versatility for high-pressure applications. With meticulous manufacturing processes ensuring seamless, annealed, and passivated tubing, this product is designed to meet the most demanding industrial standards. Whether for HPLC, gas chromatography, or other high-pressure uses, this capillary tubing is the ideal choice for engineers and technicians seeking reliable and efficient tubing solutions.

Frequently Asked Questions

What is capillary tubing made of?

Capillary tubing is made from Type 316L stainless steel, which ensures it is seamless, fully annealed, and highly durable.

How is the capillary tubing manufactured?

The manufacturing process involves: 1.Extruding the tubing from a billet of Type 316L stainless steel. 2.Re-drawing the material through a die. 3.Heat-treating in a vacuum furnace. 4.Cleaning, polishing, and passivating the tubing to achieve the desired dimensions and finish.

What applications is this capillary tubing suitable for?

This tubing is ideal for high-pressure applications such as High-Performance Liquid Chromatography (HPLC), gas chromatography, chemical processing, and analytical instrumentation.

What does the annealing process do to the tubing?

Annealing removes the temper or stiffness from the tubing, making it easy to bend and form without compromising its strength.

What are the key features of this capillary tubing?

-Small inside diameter and heavy wall for high-pressure applications. -0.064 inches outside diameter for easy connection using standard 1/16” compression fittings. -Wide chemical compatibility. -Prefinished with square, burr-free ends and interiors for minimal dead volume connections. -Cleaned, polished, and passivated for immediate use.

Can this tubing be used for biological samples?

No, this tubing is not recommended for biological samples. It is optimized for chemical and industrial applications.

Our Factory

Our factory is located the East of economically developed region.our company has two departments-technical & producing department and trade department. in titanium materials and stainless steel products research and development, production and marketing series.

Stainless Steel Capillary Tube Packing and Delivery

Related Products

Our Premium Stainless Steel Capillary Tube meet the rigorous demands of various high-precision applications. Constructed from superior grade stainless steel, this tubing offers exceptional strength, durability, and corrosion resistance